COGEN Europe Annual Conference 2025: Innovation, flexibility and efficiency for the future of european cogeneration

12.11.2025

Once again, the COGEN Europe Annual Conference confirmed itself as the key event for the European cogeneration sector. The 2025 edition, held in Brussels, brought together over 100 participants, including energy industry professionals, policymakers, and representatives from European institutions. This important gathering featured presentations offering in-depth insights on energy efficiency, emission reduction, technological innovation, and the strategic role of cogeneration in Europe’s future energy landscape. The event also provided an opportunity to celebrate excellence in the sector during the Gala Awards Dinner, recognizing those driving the industry toward new frontiers. Let’s relive the most significant moments of this edition.

Hans Korteweg

The latest

01:25

2.25.2026

Decarbonizing Hard-to-abate sectors: Biomethane as a solution

Simona D'Angelosante

Associations

02:56

2.19.2026

Cogeneration in Romania between new investments and emerging challenges

Mihai David

Market and policy

03:25

2.16.2026

The future of cogeneration in Europe: A new study on the way

Alexandra Tudoroiu-Lakavičė

Market and policy

02:25

2.9.2026

Flexibility and integration: how Europe and industry are transforming the Energy System

Janne Kerttula

Energy efficiency and cogeneration

04:12

2.5.2026

Efficient and Sustainable Nuclear Cogeneration for Industry

Sylvain Nizou

Technologies and components

03:01

1.30.2026

Data Centers and energy: Why cogeneration could be the key to the future

Thomas Smith

Energy efficiency and cogeneration

01:16

1.22.2026

Cogeneration: AssoEsco’s strategic role in the energy transition

Simona Ferrari

Associations

Case history

View allStay up to date on the world of cogeneration,

receive all the news directly in your inbox.

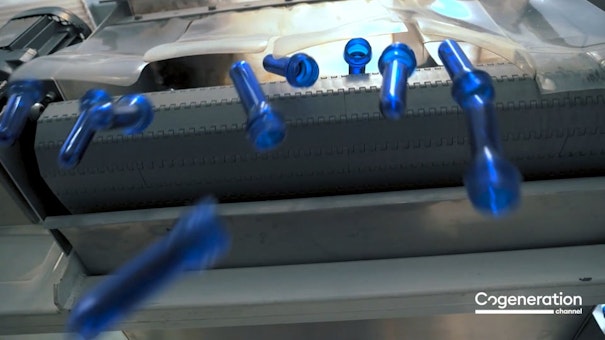

NetZero Tube: the path towards the energy transition

Climate change is a challenge and at the same time an opportunity. NetZeroTube collects ideas, insights, guides, experiences and interviews in the form of videos to accompany you on the path towards the energy transition. A path to take thanks to the energy of cogeneration, biogas and biomethane/RNG.